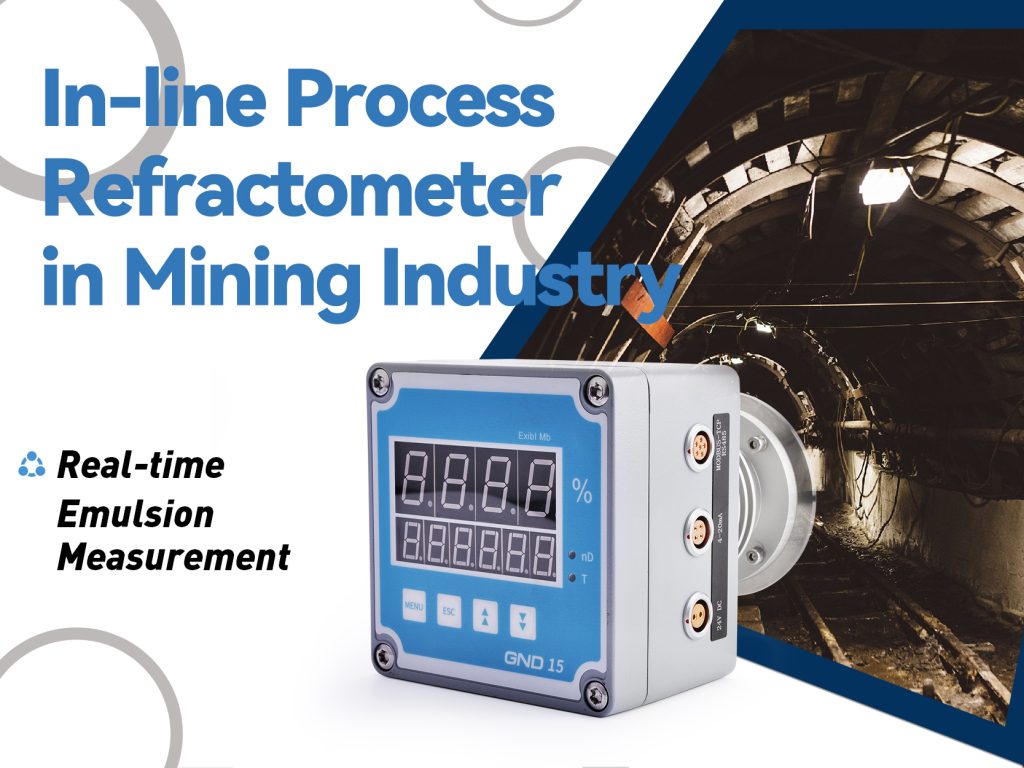

- Product Introduction:

GND-15 In-line Process Refractometer is consisting of light source, sapphire, optical receiver and signal modulation circuit. Light source signal stability of light through the sapphire contact with measured medium, refractive index will be generated by the light source through the concentration of the measured medium. The optical receiver will calculate the refractive index of the refraction light source collected and then obtains the corresponding concentration through the data algorithm. Since the concentration will be affected by temperature, it adopts the internal temperature calibration to reduce the influence of temperature drift. GND-15 can measure the solid solution content of various water-soluble industrial processing solutions and various water-soluble chemical solutions. It is a convenient instrument for quantitative management and detection in industry.

- Product Features:

- Convenient: GND-15 instrument is easy to carry and operate with high measuring accuracy and fast measuring speed;

- High Stability: GND-15 adopts sapphire refraction principle. Measuring accuracy is up to 0.3%; The instrument comes with large touch screen showing concentration %, temperature T, refractive index (nD).

- Toughness: All connection parts from the instrument are standard 316L stainless steel. With IP67 shell and mining safety certification, GND-15 can be used various harsh environment.

- Cost-efficient: The nature of this instrument can help manufacturers save lots of their cost from manual labour, water, material and energy.

- Application:

One of the main products that relays heavily on concentration measurement is Emulsion. Emulsion is widely used in coal mine production activities, especially as the working medium of the hydraulic system such as shearer, hydraulic support and hydraulic prop. It is used as power transmission, lubrication and cooling agent. It can also bring inhibitory effect on corrosion and rust. Emulsion has become the “blood” of the hydraulic system.

The performance of emulsion has great influence on the reliability, safety and service life of hydraulic system. The percentage of emulsified oil in emulsion is the concentration of emulsion. It is an important index to evaluate the performance of emulsion. Smaller concentration will affect hard water resistance, stability, rust resistance and lubricity; Higher concentration will not only increase the cost, but also reduce the defoaming ability and increase the swelling of rubber sealing material. Therefore, it is very important to realize automatic detection and matching of emulsion concentration to protect hydraulic system components, prolong their service life and reduce production costs.

- Examples of GND-15 implemented at Coal mine emulsion pump station

- Lacks of Current Measuring Method:

Nowadays, many large mines still can’t implement real-time measurement and control of the emulsion concentration in their production line. Manual measurement is still widely used as measuring method in lots of mines. This method relies on manual detection in fixed time by officers. The accuracy of manual detection of emulsion concentration cannot be guaranteed;

Manual detection of emulsion concentration completely depends on the system to maintain; Mechanical and electrical operation management workers cannot obtain continuous emulsion concentration data, and rely entirely on reporting and self-testing. Emulsion is a thick solution with large amount of foam. It is a very expensive product with low cooling ability. If the concentration of emulsion is too low, the rust resistance, bacterial inhibition and lubricity will become poor. The ratio and concentration of emulsion are affected by many factors, including water pressure, water quality, temperature, flow rate, accuracy of the ratio device, etc. Most of the existing emulsion preparation is observed by sampling with optical refractometer, which has low precision, low efficiency and is greatly affected by human factors. The GND-15 emulsion in-line process refractometer developed by ZHYQ can helps mine operators solve these problems perfectly.

- Typical Applications:

- Fine chemical products: emulsion, castor oil, pigment, paint, ink, paint, emulsion, brake fluid, antifreeze, etc;

- Chemical raw materials: alcohol, n-butanol, dimethyl silicone oil, dispersant, tripropylene glycol, ethanol, ethylene glycol, acetic acid, acrylic acid, ethyl acetate, methanol, alum, ammonium tungstate, sodium molybdate, ammonium molybdate, solvent, etc;

- Fuel oil: crude oil, heavy oil, residual oil, oil, diesel oil, lubricating oil, coal tar, electrical insulation oil, aviation gasoline, gasoline, transformer oil and other light oil;

- Slurry: mud water, sludge, coal slime water, iron pulp, pulp, paper pulp, coal water slurry, mud, etc;